If you are thinking about using the most adaptable plastic forms in industrial applications, LDPE Sheets ought to be your one-stop shop. These plastic packaging LDPE Membrane have developed the necessary resistance to various chemicals, allowing for easy formulation. The highly effective packaging sheets are the most beneficial component for various industries because they are inexpensive and environmentally friendly.

This polyethylene LDPE Membrane is used in most common applications, such as laminates and laboratory apparatus, as well as plastic toys, dispensing bottles, films, wash bottles, containers, tubes, and bags. Due to the commodity's enormous demand, it is produced in large quantities, allowing industries to purchase it at the lowest possible price. Continue reading to learn about six interesting facts about LDPE sheets.

6 Things You Should Know About LDPE Sheets

You must buy the appropriate LDPE Membrane to make the product if you are in the process of manufacturing a new one. Low-density polyethylene sheets are one of the products you ought to think about producing. You can use a specific kind of plastic to create LDPE sheets. There are numerous applications for LDPE sheets. You should be informed about this LDPE Membrane before selecting it.

1: A Less Compact Molecular Structure

First off, high-density polyethylene (HDPE) sheets and LDPE sheets are not interchangeable. They are two distinct products that differ structurally from one another. The molecular structure of LDPE sheets is distinct. More branching and molecular structures are widely dispersed. As its name implies, the product's lower density and spread-out molecular structure affect how it works, giving it greater flexibility.

2: More suppleness and flexibility

Second, unlike other plastic LDPE Membrane, LDPE sheets behave differently. They are flexible to an extent that is not possible with various plastic LDPE Membrane. The less compact molecular structure is to blame for this. As a result, the LDPE Membrane can stretch farther without breaking or suffering other damage. Additionally, the texture of the LDPE Membrane is softer. LDPE sheets are a good choice if you want to build something that feels good to the touch. LDPE sheets can be used to create finished goods that are strong, soft, and flexible.

3: Simple to Recycle

Third, you should consider the entire product life, including the end, when you are building something. Plastics of the LDPE variety are simple to recycle. The majority of recycling plants gather LDPE plastic. Due to the fact that some plastics are harder to recycle than others, using LDPE LDPE Membrane is a great idea. You want to design a product that can be recycled and given a second life, rather than ending up in landfills and clogging them up. Make sure the appropriate recycle symbol is present on any products made from LDPE sheets so that consumers are aware they can recycle them.

4: Resistant to Chemicals

Chemical-resistant products are advantageous. For instance, if you use LDPE sheets to make food packaging, you do not want the packaging to degrade in the presence of other liquids or chemicals; you want it to safeguard the food. Or, if you are producing a medical item, you will want it to be robust and resistant to harsh environments.

5: A Poor Conductor of Electricity

LD Polythene Sheet is extremely resistant to electrical shock, much like plastics. For the flexibility and detachment of electrical cables and wires, LDPE sheets are frequently used.

6: Not susceptible to high temperatures

Because LDPE sheets are thermoplastic, they maintain their original shape even at high temperatures. Typically, sheets can withstand temperatures between -40°C and 90°C. This is acceptable in typical industries because the majority of applications do not involve such high temperatures.

Different Uses for LDPE Sheets

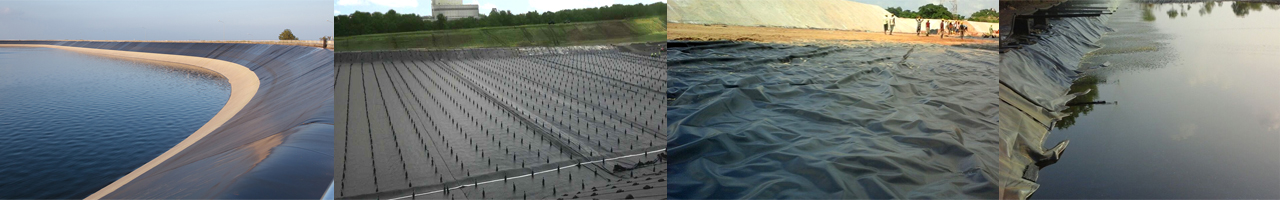

LPDE Sheets By Mono Industries

Mono Industries is manufacturing and supplying a wide range of premium quality LDPE Sheets Manufacturer that are used as the lining of canals, distributaries, Dunnage, reservoirs, industrial effluent plants, etc. These are extremely flexible, puncture-resistant, deformable, weldable, Anti-aging, anti-weathering, non-toxic, easy to install, light in weight, and strong. Our offered products are accessible in different colors, sizes, shapes, and finishes. LDPE sealability is also ideal for tarpaulins, sports stadiums, aprons and runways at airports, trenches, agricultural purposes, concrete roads, and bridges. Moreover, the said products are resistant to corrosion and are non-tearable.

Product specifications:

Minimum Order Quantity: 1000 Kilograms

Material : LDPE Membrane

Thickness: 250 microns - 1.5 mm.

Sizes: Up to 6 Meter

Additional Info: