We are all familiar with the rapidly growing demand for seafood. This resulted in technological advancements that made it possible for people to grow food in coastal marine waters and the open ocean. Aquaculture is a technique for producing food and other commercial goods, regenerating habitats, and restocking wild stocks. In the pond, where the soil is acidic and high in organic matter and sand, lining materials are used. Fisheries and aquaculture can lessen pond stressors like ammonia, hydrogen sulfide, acidic compounds, iron, and seepage of water and waste. It can also lessen soil waste buildup and erosion. The lining also reduces the time and expense needed to clean the ponds between cycles by making it simple to remove waste from the feeding areas.

In other words, the world has witnessed unprecedented growth in aquaculture—farming aquatic organisms such as fish, shellfish, and aquatic plants. This expansion has been driven by the increasing demand for seafood as well as the need to alleviate pressure on wild fish populations. As the aquaculture industry continues to evolve, innovative solutions have emerged to address various challenges. One such solution that has gained significant attention is the Fisheries and Aquaculture Sheet.

The Role of Plastic Sheets in Modern Aquaculture

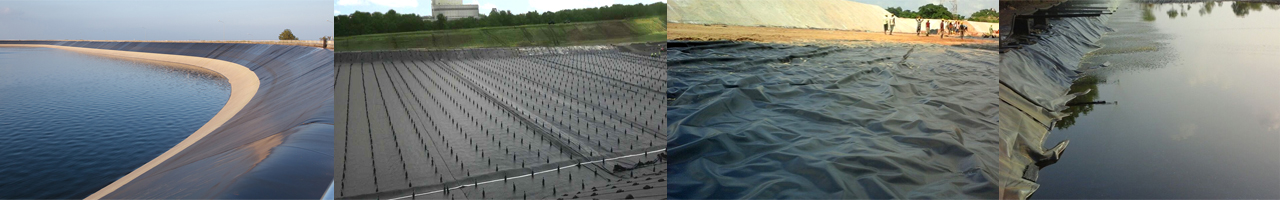

Aquaculture plastic sheets have become a cornerstone of the contemporary aquaculture landscape, revolutionizing the way aquatic organisms are cultivated and nurtured. These specialized plastic sheets are designed to create controlled aquatic environments that optimize growth, health, and overall yield. Let's delve into the multifaceted benefits that Fisheries and Aquaculture Sheets bring to the table.

1. Enhanced Water Quality Management

Maintaining optimal water quality is paramount for the success of any aquaculture venture. Plastic sheets provide an effective barrier that prevents contamination and ensures a stable aquatic environment. By acting as a shield against external pollutants and excessive sunlight, plastic sheets help mitigate the risk of harmful algal blooms, disease outbreaks, and fluctuations in water temperature.

2. Improved Growth Conditions

Fisheries and Aquaculture Sheets offer an unparalleled advantage by creating a conducive environment for rapid and healthy growth. These sheets assist in controlling water circulation and flow patterns, which facilitate the even distribution of nutrients and oxygen throughout the aquaculture system. This, in turn, fosters accelerated growth rates and ensures uniformity in size among cultured organisms.

3. Protection from Predators

In aquaculture, predation can pose a significant threat to cultured organisms. Plastic sheets act as a reliable barrier that safeguards the aquatic inhabitants from potential predators, such as birds and larger aquatic species. This protection enhances survival rates and reduces stress among cultured organisms, contributing to higher yields.

4. Optimal Space Utilization

The utilization of space is a critical consideration in aquaculture operations. Fisheries and Aquaculture Sheets enable efficient space management by allowing for the vertical stacking of tanks or enclosures. This innovative approach maximizes space utilization, making it possible to rear a larger number of aquatic organisms in a confined area.

5. Environmental Sustainability

Contrary to conventional notions about plastic's negative impact on the environment, Fisheries and Aquaculture Sheets are designed with sustainability in mind. These sheets are often crafted from recycled materials and can be reused or recycled themselves, reducing the overall carbon footprint of aquaculture operations.

Steps to Implementing Fisheries and Aquaculture Sheets

Integrating Fisheries and Aquaculture Sheets into your aquaculture venture involves a series of meticulous steps to ensure optimal results:

Step 1: Site Assessment and Design

Begin by conducting a comprehensive site assessment to determine the most suitable location for your aquaculture operation. Consider factors such as water availability, sunlight exposure, and proximity to markets. Based on the assessment, design a layout that incorporates the strategic placement of plastic sheets.

Step 2: Installation

Thoroughly clean and prepare the designated area before proceeding with the installation of the plastic sheets. Ensure that the sheets are securely anchored to prevent displacement due to water currents or adverse weather conditions.

Step 3: Water Management System

Integrate an efficient water management system that includes mechanisms for water filtration, circulation, and aeration. The plastic sheets will aid in maintaining the desired water quality parameters, but a well-designed water management system is essential for long-term success.

Step 4: Stocking and Monitoring

Introduce your chosen aquatic species into the plastic-enclosed environment. Monitor their behavior, growth, and health regularly to identify any potential issues. Make necessary adjustments to the water management system and environmental conditions based on monitoring results.

Step 5: Harvesting and Yields

As the cultured organisms reach maturity, follow best practices for harvesting to ensure minimal stress and maximum yield. The controlled environment provided by the plastic sheets will contribute to consistently high-quality produce.

Applications of Fisheries and Aquaculture Sheets

Applications of Fisheries and Aquaculture Sheets

Listed below are some of the applications where plastic sheets are used in the fisheries and aquaculture industries.

1. Extensive Pond Farming

2. Intensive/Semi-intensive Fish culture

3. Marine Farming

4. Prawn Farming

5. Extensive Brackish Water Farming

6. Intensive Sea farming

7. Shellfish Farming

8. Algae and Seaweed Farming

9. Integrated Aquaculture

Features of Fisheries and Aquaculture Plastic Sheets

1. Tear-resistant

2. Chemical resistant

3. Easy to Seal

4. Long-lasting

5. High strength

6. Temperature maintenance

7. Optimal protection

8. Extremely Strong

9. Economical

10. Highly durable

Fisheries and Aquaculture Plastic Sheets by Mono Industries

The integration of Fisheries and Aquaculture Sheets into modern aquaculture practices marks a significant advancement in the industry's quest for sustainability, efficiency, and enhanced yields. These specialized sheets play a pivotal role in creating optimized aquatic environments that foster the growth and well-being of cultured organisms. By implementing a carefully planned approach and adhering to best practices, aquaculture operators can harness the full potential of

Fisheries and Aquaculture Sheets Manufacturer by

Mono Industries to elevate their operations to new heights. Our product is non-toxic and has exceptional strength. It lasts for a very long time and offers the best protection. Additionally, due to the fact that it was produced following established industry standards and guidelines, the quality of our fisheries and aquaculture sheets never declined.

Product specifications:

Minimum Order Quantity: 1000 Kilograms

Material: Membrane

Thickness: 250 microns - 1.5 mm.

Sizes: Up to 6 Meters

Additional Info:

Pay Mode Terms: NEFT/RTGS/Cheque

Delivery Time: 5-7 days

Port of Dispatch: Delhi & Haryana

Production Capacity: 600 Tons Monthly